{formbuilder:40269}

Description

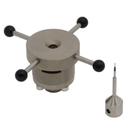

We have many options for puncture testing equipment. We can have fixtures built to fit your particular machine or we can provide a full system solution.

The following information is required to quote a puncture fixture. Some of these questions may not be relevant depending on the type of puncture test.

- What is the material being tested?

- Are there any ASTM standards being followed?

- What is the required diameter of the probe?

- What is the required diameter of the lower fixture opening?

- What is the force range of the test?

- Requesting a full system or just the fixture?

Puncture strength tests are used to determine the puncture or rupture characteristics of a material. This is generally a test where a material is compressed by a probe or other type of device until the material ruptures or until the stretch limit is achieved.

Puncture testing is commonly used to determine the strength of a material such as film, rubber or membrane. Puncture testing may be used in medical applications for determining the sharpness of a syringe, scalpel or blade or to measure the resistance and pliability of synthetic skin.

Puncture resistance is the relative ability of a material to inhibit the progression of a tear once it has been pierced by a cut or a nick. Performed under standard conditions, the test imparts a biaxial stress that is similar to the type of stress encountered in many product end user applications. The puncture resistance will depend on the nature of puncture attempt, with the two most important features being point sharpness and force.

An example of a material that is used extensively is Stretch wrap film. It is an extremely important packaging material used in applications from heavy duty pallet strapping to sealing food items in containers to keep them fresh. Puncture resistance is a important parameter puncture strength with regards to preventing accidental puncture damage thereby helping to maintain product freshness.

| Test Standards

- ASTM D5635 / D5635M - 11 Standard Test Method for Dynamic Puncture Resistance of Roofing Membrane Specimens

- ASTM D4833 - 07 Standard Test Method for Index Puncture Resistance of Geomembranes and Related Products

- ASTM F1306 - 90(2008)e1 Standard Test Method for Slow Rate Penetration Resistance of Flexible Barrier Films and Laminates

- ASTM F2878 - 10 Standard Test Method for Protective Clothing Material Resistance to Hypodermic Needle Puncture

- ASTM F2132 - 01(2008)e1 Standard Specification for Puncture Resistance of Materials Used in Containers for Discarded Medical Needles and Other Sharps