Plastics used in cars, airplanes, construction and certain consumer goods must be able to withstand intense pressure before breaking. To ensure plastic components perform in the field and don’t fail prematurely, those who design, manufacture and evaluate the quality of plastics rely on tensile tests. These tests, which are typically conducted with test stands and wedge grips, evaluate how plastics perform under stress and measure how much force is required to break a specimen.

Acceptable force limits vary by material and industry. These limits are defined by standards like ASTM D638, which was designed for both reinforced and unreinforced plastics from 1 mm to 14 mm thick.

If you need to test to ASTM D638, here’s what you need to know, including what equipment is required and how to conduct the test.

A Brief Introduction to ASTM D638

ASTM D638 is widely used to test the tensile properties and durability of plastics across industries. In addition to strength, ASTM D638 testing can be used to measure the elongation and stiffness of materials. Testing to the standard helps R&D professionals determine which materials to use in production, and quality control professionals ensure products are ready to send to channel partners or consumers.

How to Prepare a Specimen for ASTM D638 Testing

There are five types of specimens allowed under the standard: Types I, II, III, IV and V. While the length, width and thickness of the types vary, all specimens must be flat and dumbbell or “dogbone” shaped. To create the dogbone shape, the plastic specimen can be made with injection molding or machining. A die cutter can be used to create a sample from an already formed component or a larger piece of material.

ASTM D638 Testing Equipment

To conduct an ASTM D638 tensile test, you will need:

- ASTM D638 Sample Cutter Die: Used to create a dogbone-shaped specimen that meets ASTM D638 specifications

- Motorized Test Stand/Universal Testing Machine: Used to pull the specimen and collect data about the plastic’s tensile properties

- Wedge Grips: Used to hold the specimen securely in place during testing

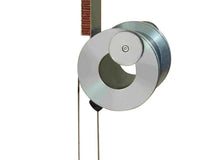

- Extensometer: Used to test the stretchiness of the plastic (modulus of elasticity); extensometers clip on to the sample or use video

How to Conduct an ASTM D638 Test

Step 1: Prepare Your Specimens

Cut or mold your material into one of the standard’s five approved dumbbell shapes. Ensure your specimens meet the length and width requirements most appropriate for your material’s thickness and rigidity.

Step 2: Set Up the Test

Mount your specimen securely in the grips of your testing machine and attach the extensometer. Set your test speed according to the material specification (rates typically range from 1 to 500 mm/min).

Step 3: Run the Test & Collect Results

Start the test by pulling the specimen at the specified rate until it breaks. The system will record force and displacement data throughout the test cycle.

Rely on JLW Instruments for Your ASTM D638 Testing Needs

JLW Instruments carries all the equipment needed to conduct ASTM D638 tensile tests, including sample die cutters, extensometers, wedge grips, and universal testing machines – like Mark-10’s Series F motorized test stand or Lloyd Instrument’s LS Series test stand. Our solutions help testing labs and manufacturers ensure results are accurate and repeatable.

If you need help selecting the right equipment, contact us to speak with a tensile testing expert.